Archival picture framing is the best means to protect valuable original art, prints, posters, photographs, certificates, diplomas, sports memorabilia, and more.

Read More “Archival Picture Framing: The Top 3 Tapes You Need”Watch a professional framer use Pro Tapes® adhesives to frame with fillets

Recently, Pro Tapes® commissioned a local shop to frame some of our corporate collection. In the process, we wanted to get a closer look at how our tapes are used by framers. This is the first of four pieces we framed to profile on our blog, it’s a print advertisement, a single page mounted and framed with chrome fillets. Read More “Watch a professional framer use Pro Tapes® adhesives to frame with fillets”

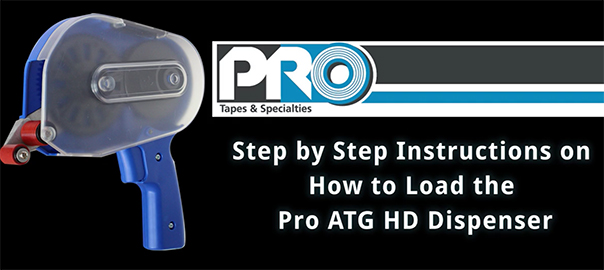

Step by Step Instructions on How to Load the Pro ATG HD Dispenser

ATG Tape is an adhesive transfer tape where the adhesive is “reverse wound” meaning the adhesive is wound on the outside of the roll, ideal for use in an adhesive transfer gun where the tape is threaded around the roller at the nose of the gun adhesive side out.

To operate the ATG gun you squeeze the trigger, Read More “Step by Step Instructions on How to Load the Pro ATG HD Dispenser”

3 Reasons You Should Be Using ProTapes ATG Tape For Your Arts & Crafts Projects

Whether you’re a professional or hobbyist, using Pro 154 and Pro 156 ATG is more convenient than using double-coated tape and much safer than liquid adhesives for any arts & crafts project.

ATG tape is double-sided adhesive dispensed using an ATG gun. Its already the go-to tape for professionals in many fields. Now, more and more people are turning to ATG for their arts & crafts projects.

Here’s 3 reasons you should be using ATG on your projects: Read More “3 Reasons You Should Be Using ProTapes ATG Tape For Your Arts & Crafts Projects”