About Rotary Die-Cutting at Pro Tapes®

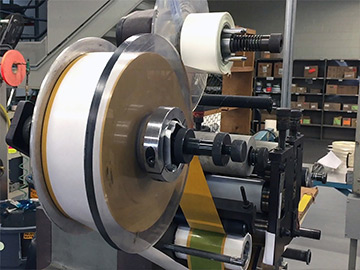

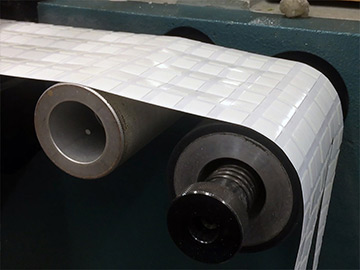

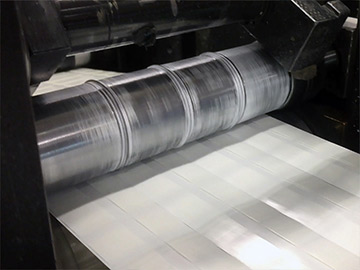

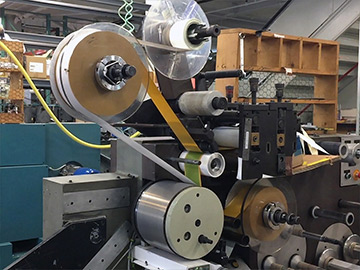

Pro Tapes® has multiple machines with high speed rotary die capabilities. A rotary die cutting machine is electrically operated and uses a rotating cylindrical die. The engraved rotary tool allows for the tightest tolerances. Material that is feed through gets cut by the rotary tool into smaller parts, shapes, or perforations.

Rotary die-cutting works well with most substrates, yields higher production rates and greater precision (for better quality parts), with the ability to perform multiple functions (such as printing, perforating, and laminating).

Meet Our Converting

Business Manager

Chris Hart

VP of Sales & Marketing

Learn more on our

Meet the Team page.

Rotary Die-Cutting Capabilities

- Can process thicker and larger parts

- Repeats lengths from 6” up to 39.37”

- Can be processed in roll form or individual parts for more efficient customer use

- Faster processing, more cost effective

- Parts and liners can be printed as well as die-cut

- Laminate up to 4 materials inline and multi-layer cut

- Web widths up to 300mm

- Waste/scrap ejection

- Solid dies, flexible dies, floating dies, vacuum and air ejection

Image & Video Gallery

Packaging Solutions

Pro Tapes® provides custom printing and custom packaging solutions, along with in-house design and support. Raise brand awareness, and keep your product looking fresh. Learn more.