It doesn’t matter if you’re a novice to the tape industry, been entering or processing orders for some time or an experienced veteran selling adhesives for years; there’s always more to learn about the applications in which tape is being used. The Pro Tapes® Solutions Team is here to assist you through the process of selecting the right tape product for your adhesive needs. Time, temperature, conditions and surface are four factors to consider when determining the suitability of a tape product for the application.

1: Time

Initial thoughts on time usually steer towards, how long a tape will remain on the intended surface, such as: hours, days, months or years? Will the tape be intended for temporary or permanent use? Although it’s usually an afterthought, or not a thought at all to your average user, it’s just as important to ask: does the bond strength need to be immediate or stronger over time? Most adhesives will cure and reach maximum bond after 24 hours.

2: Temperature

What is the max temperature resistance that needs to be met and for how long? Is short term or long term high temperature resistance required? An application may require intermittent or short term exposure to 400°F baking cycles and remove cleanly when done. This is often a requirement in automotive masking tapes used in automobile body painting. An example of long term temperature resistance may be exposure to heat and freezing temperatures permanently. Pro Tapes® has a variety of butyl tapes, like Pro® Flex, that are made for waterproof sealing and remain stable (even in fluctuating changes) in temperatures from -70°F to 200°F. Pro Tapes® liner of butyl and EHB tapes are unique because they are permanent and can withstand extreme changes or fluctuations in weather temperature or conditions within hours.

3: Conditions

What elements will the tape be exposed to? Will the tape be used indoors or outdoors? There are many factors to consider in regards to conditions. Some indoor factors include: storage conditions, humidity, chemicals and dust. Some outdoor factors include: UV rays, water, wind, ice, humidity, chemical and acid contact. Exposure to outdoor elements such as submersion under chlorine or salt water or air pressure during aviation can cause strain on the shelf-life of some tapes.

4: Surface

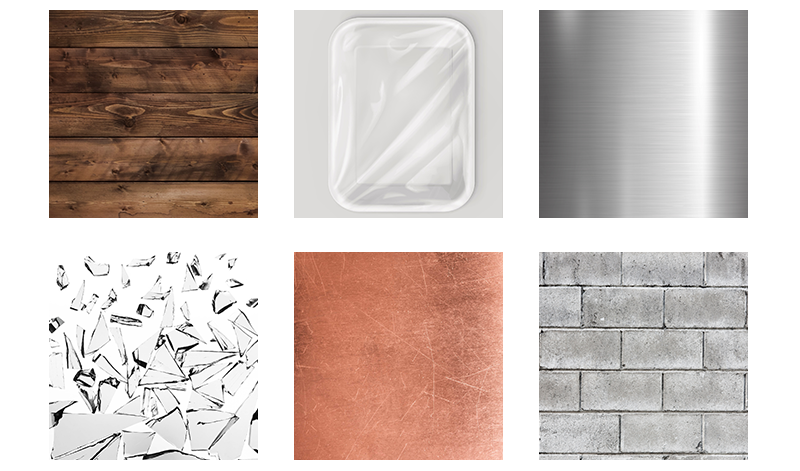

What type of surface is the tape adhering to? Is this a LSE or HSE surface the tape is adhering to? LSE or Low Surface Energy is solvent less surfaces and can’t handle high temperatures. Some examples of LSE surfaces are some plastics (fluoride film, acetal), polypropylene, polystyrene, polyethylene, polyvinyl, PTFE and powder coated paints. HSE or High Surface Energy solvent based surfaces that can handle high temperatures. Some examples of HSE surfaces are metals (copper, zinc, tin, aluminum, lead, stainless steel, glass porcelain) and some plastics (kapton film, PVC, polyester, epoxy, paint, polyurethane paint and polycarbonate). Another complicated surface to consider is direct skin contact. Usually, the higher the surface energy the higher the adhesion that is required to stick.

Visit Our Online Tape Catalog

We encourage you to visit our online tape catalog and browse through our adhesive tape products to learn more. Pro Tapes® online tape catalog is designed to assist you in locating the adhesive product that best suits your needs. There are three different filters: Type, Application and Feature. If you know that you need a paper based product that will be used for color coding and labeling but also needs to remove clean, you can select those options and results will first display products that meet all three criteria (Artist Tape and Pro® 46). Our product selector functionality will also display the results of tapes that meet two or maybe only one of the criteria options.

Please feel free to ask our expert solutions team by completing the form below.