With the variety of converting machine types available today it is difficult to determine which is best. For many small converters large automated wide web machines are just financially out of reach. Not enough volume of any one item to justify a large cap expenditure puts most companies in a position where they would be working in the most inefficient way. As a result, the actual volume by item ends up being the deciding factor for most converters when deciding how to allocate funds for new equipment. ProTapes, unlike most converters, has every type and size machine to produce any size order which is rarely seen at the manufactures level.

- 1. Cost

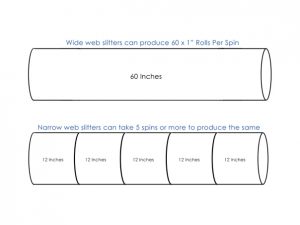

The yield per spin cycle when cutting from a wide web more than QUADRUPLES any narrow web slitter’s production. Slitting directly from master or jumbo rolls using a wide web slitter is the most cost effective slitting method out there. This is because narrow web slitters require an intermediate pony rolls be cut from jumbo rolls, which requires the material to be handled twice, once to make the intermediate roll & then again to produce the finished roll. Of course, this all adds up to extra labor costs and waste.

The yield per spin cycle when cutting from a wide web more than QUADRUPLES any narrow web slitter’s production. Slitting directly from master or jumbo rolls using a wide web slitter is the most cost effective slitting method out there. This is because narrow web slitters require an intermediate pony rolls be cut from jumbo rolls, which requires the material to be handled twice, once to make the intermediate roll & then again to produce the finished roll. Of course, this all adds up to extra labor costs and waste.

Example:

60″ Wide web jumbo slitting 1″ wide rolls will yield 60 rolls per/per spin12″ Narrow web cutting 1″ wide rolls will yield 12 rolls per/per spin

- 2. Quality

- Our new state-of-the-art wide web slitting machines are built with advancements such as tension controls, differential rewinding and automatic blade positioning. Other functionality such as automatic finished roll cut-off and discharge along with automatic core reloading, helps eliminate human error through technology, including programmable product recipe storage for every substrate and size you slit. These types of features provide converters with the means to repeat any process at any time with very minimal set-up time and labor. Producing only the very best quality the first time every time.

On the other hand, the vast majority of narrow web slitters are only equipped with basic features and involve significantly more human interaction. More human interactions lead to more time and potential for errors.

On the other hand, the vast majority of narrow web slitters are only equipped with basic features and involve significantly more human interaction. More human interactions lead to more time and potential for errors. - 3. Waste / Scrap

- Cutting down master rolls into intermediate rolls for a narrow web slitter requires the operator to first web the machine generating unnecessary waste then based on the usable width of the narrow web slitter, operators may need to slit various size rolls trying to optimize the machine’s full width. Also, you may be forced to split the web width into many non-standard intermediate rolls unable to utilize the full width of the narrow web slitter its converted on.

These types of issues result in lost time, material and ultimately profit. While each machine type and functionality provides unique solutions to the substrate being converted by having the right type of machine available is critical. Here at ProTapes we house an array of slitting equipment designed and arranged to handle any order size produced from any size raw material. Whether it is a log roll, intermediate roll or a full width master we have the technology and equipment to provide any solution when it comes to converting both pressure sensitive and non-pressure sensitive substrates.