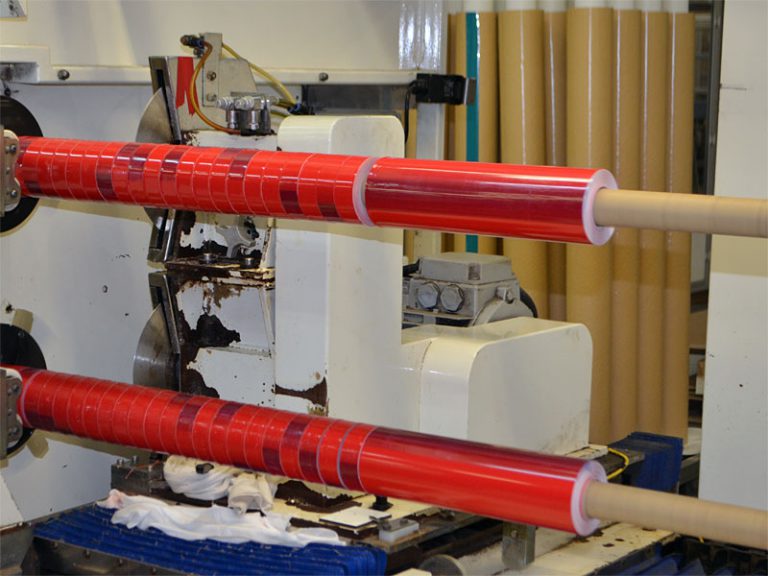

ProTapes has equipment to do many types of slitting. When possible wide web slitting is preferred by most customers because of the cost benefits associated with its high volume output. But when is it better to chose a lathe slitter to convert your materials? Below are 5 scenarios where lathe slitting is your best option.

- 1. Small runs

When converting from jumbo rolls, the efficiency gained for larger jobs on a wide web slitter is great. However, often times, order minimums required for wide web slitting can far exceed the customer’s requirements, and that’s one situation lathe slitting is a great option.

When converting from jumbo rolls, the efficiency gained for larger jobs on a wide web slitter is great. However, often times, order minimums required for wide web slitting can far exceed the customer’s requirements, and that’s one situation lathe slitting is a great option.- 2. Narrow widths

- Although a rotary die tool slitting can also be used for widths below 12mm, it requires an upfront investment in an expensive rotary die tool. On the other hand, the lathe slitter produces perfect rolls with no tooling required! This means high quality finished goods with small minimums.

- 3. Multiple widths within a web

- Lathe slitting gives us the opportunity to cut a single web into multiple widths utilizing our programmable PC, meaning the customer can purchase multiple widths within a single log to keep the minimum per size very low.

- 4. Set up times

- Each of our lathe slitters is programmed via a computer and set up is as quick as typing some data. We can also maintain the perfect cut over time by storing the precise “recipe” for your specs in our computer. This means the PC will remember your settings making future slitting more efficient and consistent generating the same quality every time.

- 5. Multiple core options

- ProTapes state-of-the-art fully automated lathe slitters have multiple core options we currently have 1”, 1.5” and 3” inside diameter (ID) mandrels giving the customer multiple options. The change over from one size core ID to another is minutes eliminating long set up times that are associated with the same type change over on a rewind slitter.