When it comes to die cutting material, with or without pressure sensitive adhesive (PSA), two of the more commonly used methods are flatbed & rotary. When choosing which method is best suited for producing your die cut parts, it’s always great to have options and at Pro Tapes & Specialties, we always have the right tool for the job.

Die cutting with a flatbed press or a rotary machine offer their own unique advantages, and in some cases, disadvantages, so determining which method to use can often mean the difference between success or failure in terms of landing that new piece of business or missing out on that new opportunity.

Let’s look closer at each type of machine, first a flatbed die cutting press and then a rotary die cutting machine:

Flatbed Die Cutting

A flatbed die cutting press is a hydraulically operated machine which uses a steel rule die to “click cut” or punch out die cut parts by driving the die in a downward motion through the material.

Flatbed Advantages:

- Less expensive tooling because steel rule dies are often less expensive than rotary dies.

- The ability to cut through much denser, thicker materials.

- The ability to more closely group or nest parts, so waste & scrap are reduced.

Flatbed Disadvantages:

- A slower rate of production vs rotary die cutting.

- Longer setup times.

- It cannot print, perforate or laminate.

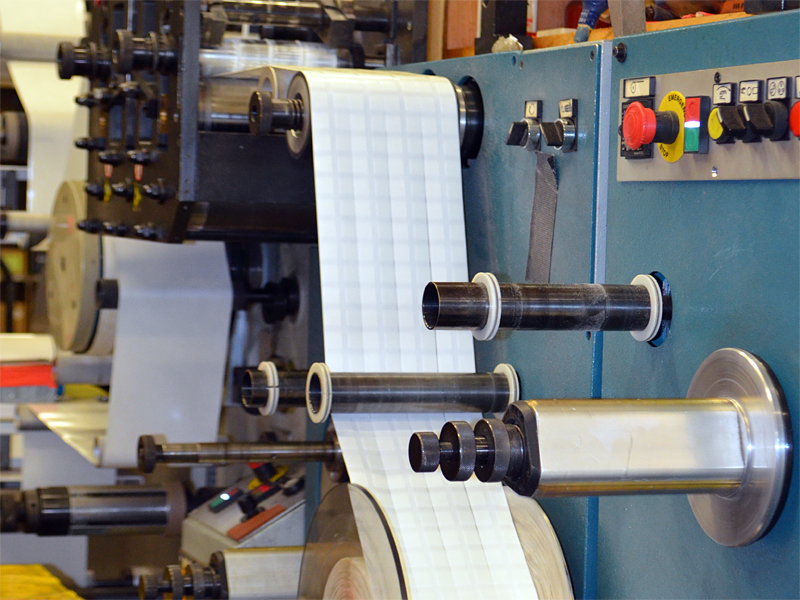

Rotary Die Cutting

A rotary die cutting Machine is electrically operated and uses a rotating cylindrical die, in which the material is feed through, this is also known as a die station, which holds a rotary tool that will cut the sheet or web into smaller parts, shapes or perforations.

Rotary Advantages:

- Higher production rates, the ability to produce a far greater number of parts & pieces per production cycle.

- Much greater precision and accuracy in terms of the quality of die cut parts produced.

- The ability to perform multiple functions such as printing, perforating and laminating.

Rotary Disadvantages:

- Engraved dies are expensive to purchase and maintain.

- Require larger production runs to justify costs associated with set-up and tooling.

- Not as well suited for thicker, more dense materials.

Ultimately the choice between flatbed & rotary die cutting comes down to the unique requirements that each project presents such as the material being die cut, the volume associated with the project and the long term viability of the business. These are all contributing factors to which tool best fits the job at hand but no matter what your job calls for, Pro Tapes & Specialties has the equipment and expertise to see your project through to success!