There are a considerable number of filament strapping tapes on the market. Each one can vary in tensile strength, backing and adhesive systems. This can make it difficult to choose the appropriate tape for your specific application and needs.

Industries that frequently uses the Filament Strapping tapes include:

- Packaging/Reinforcement of Heavy Cartons

- Food & Beverages

- Electronics

- Appliances, Furniture, and transportation/delivery of such

- Automotive-Parts

- Energy-Oil, Gas, pipe and conduits.

- General Manufacturing—Metalworking

In this blog post, we’ll take a look at the three most common applications for filament strapping tapes, and give you our product recommendations for each.

For Bundling, Palletizing and Sealing Corrugated Boxes, Choose Filament Tapes

Filament tape is well known for its bundling and reinforcing capabilities. Tensile strength for filament strapping tapes range from 100lbs to 600lbs per square inch. But what exactly is filament tape?

Filament tape is a pressure sensitive adhesive (or PSA) constructed of polypropylene or polyester film. It is glass-reinforced, with a natural rubber based adhesive system.

The glass (or fiberglass composite material) is embedded directly into the adhesive backing in “filaments.” This provides additional strength and makes the tape resistant to tears, scuffing, splitting and abrasion. These tapes can be reinforced with polyester, polypropylene, fiberglass fibers or yarn filaments.

Our Recommended Filament Tapes

For packaging/sealing boxes, we recommend Pro® 180 (100lbs 4mil utility grade Fiberglass Filament Tape.)

Pro® 180 is designed with an aggressive rubber based adhesive. It is cost effective and has outstanding holding power, making it ideal for packing products for shipment.

For palletizing/bundling, we recommend our Pro® 166 (200lbs 5.5mil Industrial Grade Fiberglass Reinforced Strapping Tape, with a synthetic rubber based adhesive.)

Pro® 166 is a clear, uni-directional filament tape ideal for medium strength duty jobs. Thanks to the tape’s transparency, you can see printed information and illustrations through it.

For Securing Appliances and Furniture, Choose Tensilized (Non-Filament) Polypropylene Strapping Tapes

Tensilized Polypropylene strapping tape (or, TPP) is also commonly known as Appliance Tape. It is a non-staining, strong tensilized polypropylene backing coated with a rubber adhesive system.

This tape is specially designed to be stain and adhesive transfer resistant. It features high tack, high adhesion, high shear and chemical resistance. It is also waterproof and non-toxic.

TPP or Appliance Tape is ideal for delivery heavy products such as appliances. This PSA naturally shrinks to secure the load when used. Since it does not contain filaments, it will stretch a fair amount before breaking but will instantly snap into place when loads shifts. It has a low elongation and high tensile strength.

Our Recommended Strapping Tape

We recommend Pro® 188 (4.6mils White TPP tape) for closing and bundling appliances and parts (such as refrigerator doors, shelves, etc.) securely in place during transport.

Other applications for Pro® 188 include securing and bundling computers, furniture and office equipment.

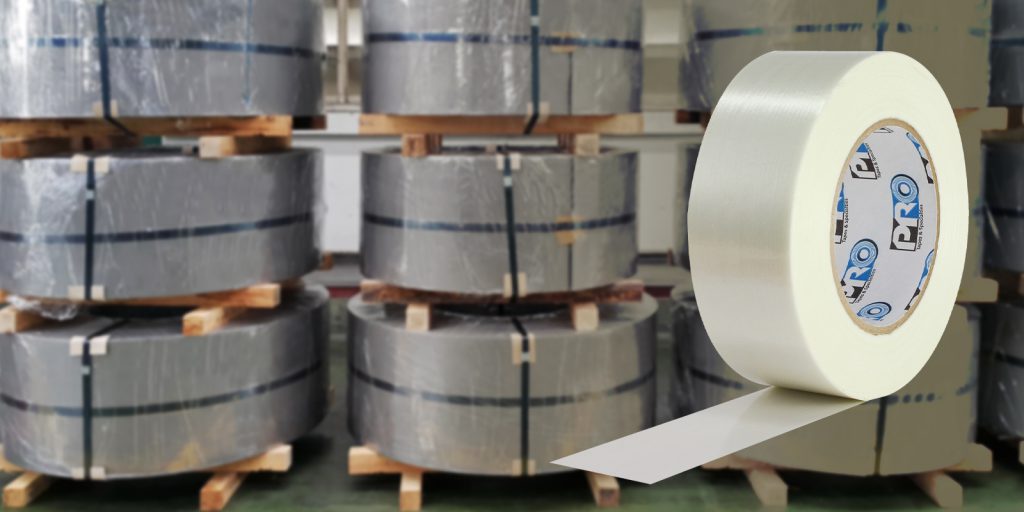

For Coil Tabbing, Choose Heavy Duty Polypropylene Strapping Tapes

Polypropylene strapping tape is also known as Poly strapping or PP Strap tape. It is a thermosplastic material made with a tensilized polypropylene backing and a rubber adhesive system.

Our Recommended Poly Strapping Tape

Coil tabbing and pipe bundling require a high tensile strength and low stretch.

That’s why we recommend Pro® 167 (300lbs 6mil general purpose polypropylene reinforced glass yarn filament tape.)

Pro® 167 is one of our strongest options for bundling and palletizing heavy items. The glass yarn filaments provide added strength for high impact and elongation, while protecting the tape against delamination.

Choose Pro Tapes® as Your Filament Strapping Tape Supplier

If you still require additional assistance in choosing the best strapping tape for your application, please reach out to us any time at sales@protapes.com and we will be more than happy to help.

Pro Tapes® is also capable of offering customized products. Our 150,000 Sq. ft. facility is equipped with a full range of state-of-the-art converting and custom packaging equipment. Our highly equipped facility allows us to offer custom solutions while reducing lead times and assuring consistently high quality products.