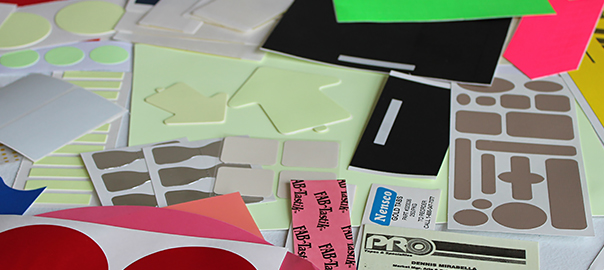

When it comes to pressure sensitive adhesive tapes most of the time you think of rolls of tape, after all, everyone has used a roll of tape. When it comes to actually applying tape, however, most people use it in strips or in pieces, either to help mask a surface, close a box, or hold something in place. Although roll goods are certainly the easiest and most convenient way to buy and sell tape, when it comes to actually using the product, roll goods aren’t always the easiest or most efficient way to go. That’s where the specialty die-cutting services at Pro Tapes® comes into play.

When it comes to pressure sensitive adhesive tapes most of the time you think of rolls of tape, after all, everyone has used a roll of tape. When it comes to actually applying tape, however, most people use it in strips or in pieces, either to help mask a surface, close a box, or hold something in place. Although roll goods are certainly the easiest and most convenient way to buy and sell tape, when it comes to actually using the product, roll goods aren’t always the easiest or most efficient way to go. That’s where the specialty die-cutting services at Pro Tapes® comes into play.

Here are 4 Ways the Die-Cutting Services at Pro Tapes® Can Help Your Business Succeed…

1. Custom die-cutting helps speed up your production and improve efficiency:

Let’s say you’re application calls for a very specific and precise surface to be masked off to protect it during a painting or coating process. You can spend time having someone try to mask the area off by hand, cutting the tape so that it covers the desired portion of the surface. Each time the masking process is repeated, it becomes less accurate and takes more time. With customized die-cut pieces, the same precise masking area is covered each time and applied in half the time it takes to cut the tape by hand.

Let’s say you’re application calls for a very specific and precise surface to be masked off to protect it during a painting or coating process. You can spend time having someone try to mask the area off by hand, cutting the tape so that it covers the desired portion of the surface. Each time the masking process is repeated, it becomes less accurate and takes more time. With customized die-cut pieces, the same precise masking area is covered each time and applied in half the time it takes to cut the tape by hand.

2. Interlined pre-slit strips are much easier to work with:

2. Interlined pre-slit strips are much easier to work with:

Have you ever tried to lay a strip of tape down in a very small or narrow cramped area that needed to be very precise? Working with a pre-determined die-cut strip makes applying tape just that much easier, plus by adding a liner it makes it much easier to reposition the tape so that it’s applied exactly in the desired place.

3. Combining multiple tape products into one easy to use die-cut part or piece:

Many times applications call for the use of two or three different types of adhesive tapes. For example, your application may call for a clean removing sensitive adhesive system but with a high strength chemical resistant backing. Our clients often come to us with request asking for a tape with an adhesive like one product, but with the backing like another. Good luck asking a manufacturer to mix & match their adhesives with their various backing materials! With Pro Tapes® specialty fabricating and laminating services, however, combining multiple tape products into one user friendly solution is much easier than you would think.

Many times applications call for the use of two or three different types of adhesive tapes. For example, your application may call for a clean removing sensitive adhesive system but with a high strength chemical resistant backing. Our clients often come to us with request asking for a tape with an adhesive like one product, but with the backing like another. Good luck asking a manufacturer to mix & match their adhesives with their various backing materials! With Pro Tapes® specialty fabricating and laminating services, however, combining multiple tape products into one user friendly solution is much easier than you would think.

4. Printing, perforating and scoring:

Being able to have the tape you’re using tear in the exact same place every time you need it to may sound like a pipe-dream, but with Pro Tapes® perforating capability we can make sure each roll tears exactly in the same place every pre-determined length. Need instructions or a logo printed on your product? No problem, Pro Tapes® can print on just about any tape product or release liner there is! Need that same liner to split down the middle so it’s easier to work with during an assembly process? Our score cutting process makes it much easier to remove liners and apply products.

Being able to have the tape you’re using tear in the exact same place every time you need it to may sound like a pipe-dream, but with Pro Tapes® perforating capability we can make sure each roll tears exactly in the same place every pre-determined length. Need instructions or a logo printed on your product? No problem, Pro Tapes® can print on just about any tape product or release liner there is! Need that same liner to split down the middle so it’s easier to work with during an assembly process? Our score cutting process makes it much easier to remove liners and apply products.

With our 40 years of specialty converting experience, Pro Tapes® specializes in not only providing our customers with the correct adhesive tape for their specific application, but we also help provide the product in the most user friendly put-up possible.

Pro Tapes® has multiple machines with high speed rotary die capabilities. from ProTapes & Specialties, Inc. on Vimeo.

Flatbed Die Cutting Thick Medical Foam from ProTapes & Specialties, Inc. on Vimeo.